Hövelhof, 21 November 2025 – CUP&CINO is excited to announce the acquisition of the TONE brand. The global distribution network for TONE coffee systems will be fully integrated into the CUP&CINO GROUP. CUP&CINO, headquartered in Hövelhof for 30 years, is making a clear statement with this move: consolidating expertise and expanding its international distribution network. Financial details of the transaction were not disclosed.

With the integration of TONE, the CUP&CINO GROUP grows to a total of four strong brands: CUP&CINO, Latte Art Factory, BaristaOne, and TONE. While CUP&CINO operates as a concept provider in Germany and Austria, Latte Art Factory, BaristaOne, and TONE form the International Division – focusing on technological excellence in the coffee industry.

Two Innovation Leaders Combine Their Strengths

Expanding the product portfolio is a strategic step to create targeted synergies for customers worldwide. TONE is known for its state-of-the-art, energy-efficient brewing systems and minimalist Swiss design, which combines functionality and sustainability. TONE machines set standards in precision, temperature control, and energy efficiency – making them a perfect complement to the milk and coffee systems from Latte Art Factory and BaristaOne.

“With TONE, we are expanding our portfolio with the leading brewing technology in the batch coffee segment – a missing puzzle piece that completes our vision of being a holistic solution provider for the coffee industry,” explains Frank Epping, Founder and CEO of the CUP&CINO GROUP. “Together, we will offer our customers everything from a single source – from the perfect milk solution and fully automatic machines to the most innovative brewers in the industry.”

Shared Values and a Common Vision

Both CUP&CINO and TONE stand for continuous technological innovation, the highest quality equipment, and a premium experience for their customers. The combination of these values forms the foundation for sustainable growth, expanded market presence, and the strengthening of existing partnerships.

“The integration of TONE in our portfolio fits perfectly in pursuit of quality, reliability, and innovation,” adds Sven Keysers, CEO of the International Division at CUP&CINO. “It’s not just about expansion, but also about building trust – cup by cup and relationship by relationship. Ultimately, it’s all about the customer experience: providing people worldwide with an exceptional coffee experience that combines technology, craftsmanship, and emotion.”

Holger Welz, founder of TONE, also emphasizes: “I am pleased that TONE technology and products can now be integrated into a larger portfolio of premium products and that the CUP&CINO GROUP shares our values and will consistently drive technological advancement and the international distribution of TONE products. This partnership opens up new opportunities for our customers worldwide.”

Continuity and Integration

The TONE team will be integrated into the CUP&CINO GROUP. Existing partnerships and business relationships will continue unchanged. Customers will also benefit from the expanded product portfolio and the global network of the Latte Art Factory and BaristaOne brands.

In the short term, the focus is on the seamless integration of the team and the successful continuation of ongoing projects with existing TONE partners. In the long term, the group aims to become one of the world’s leading providers of premium coffee technology with complete solutions from a single source.

In today’s café environment, hygiene is essential, not just for compliance, but for building trust with customers and ensuring consistent drink quality. Whether using a traditional steam wand, or the Latte Art Factory, the design of the system plays a major role in supporting food safety and operational efficiency.

The Latte Art Factory is the most hygienic milk foaming solution on the market because it automates all cleaning processes, eliminating operator error and ensuring consistent hygiene with minimal effort. Unlike other automated systems that still depend on manual purging, cleaning routines, or staff diligence, the Latte Art Factory features built-in flushes after every drink, automatic daily cleaning cycles with approved agents, and system lockouts if protocols aren’t followed. It also logs every cleaning action for full traceability and HACCP compliance, making it effortless for staff and worry-free for operators.

Many milk foaming systems follow hygiene best practices through scheduled CIP (clean-in-place) cycles and start-up rinses. These approaches are effective when followed consistently, but typically require manual initiation and tracking. This can introduce variability in daily operations, especially during busy shifts or across multiple users.

Latte Art Factory is designed to reduce variability by automating key hygiene steps:

Automatic water flush after each drink

Timed daily CIP cycles using approved cleaning agents

Built-in system lock if cleaning is overdue

Full digital log of all hygiene activity for easy audit readiness

These features ensure cleaning protocols are not only performed regularly but also fully integrated into the workflow, helping to meet strict food safety standards with ease.

Traditional steam wands are a proven tool in coffee service, but maintaining hygiene depends entirely on manual routines: purging after each use, soaking components, and monitoring residue buildup. Without regular cleaning, milk residue can cool within the wand and become a risk area for microbial growth, particularly during low-volume periods.

While steam sterilizes external surfaces, internal areas may not reach the same level of hygiene without deeper disassembly and cleaning.

| Aspect | Latte Art Factory | Other automated systems | Steam wand |

|---|---|---|---|

| Automatic flush after drinks | ✅ Yes | ❌ Not standard | ❌ Not built-in |

|

CIP enforcement |

✅ System-locked | ❌ Optional/manual | ❌ Manual soak |

| HACCP log availability (meets food safety standards) |

✅ Automatic log | ❌ Manual records | ❌ Manual records |

| Allergen separation (allergy prevention) |

✅ Closed loop system | ⚠️ Depends on setup | ❌ Manual jug handling |

| Workflow integration | ✅ Seamless | ⚠️ Varies | ❌ Fully manual |

| Burn risk | ✅ No steam | ✅ Low | ❌ High (open steam) |

Hygiene in cafés is a shared responsibility between tools, workflows, and people. Systems that automate key cleaning steps reduce operational complexity and support teams in maintaining high hygiene standards throughout the day.

Latte Art Factory makes hygiene simple, consistent, and trackable, so cafés can focus on delivering exceptional drinks with confidence.

Get in touch today to get your own!

That’s not a hypothetical anymore. It’s already happening in Sweden.

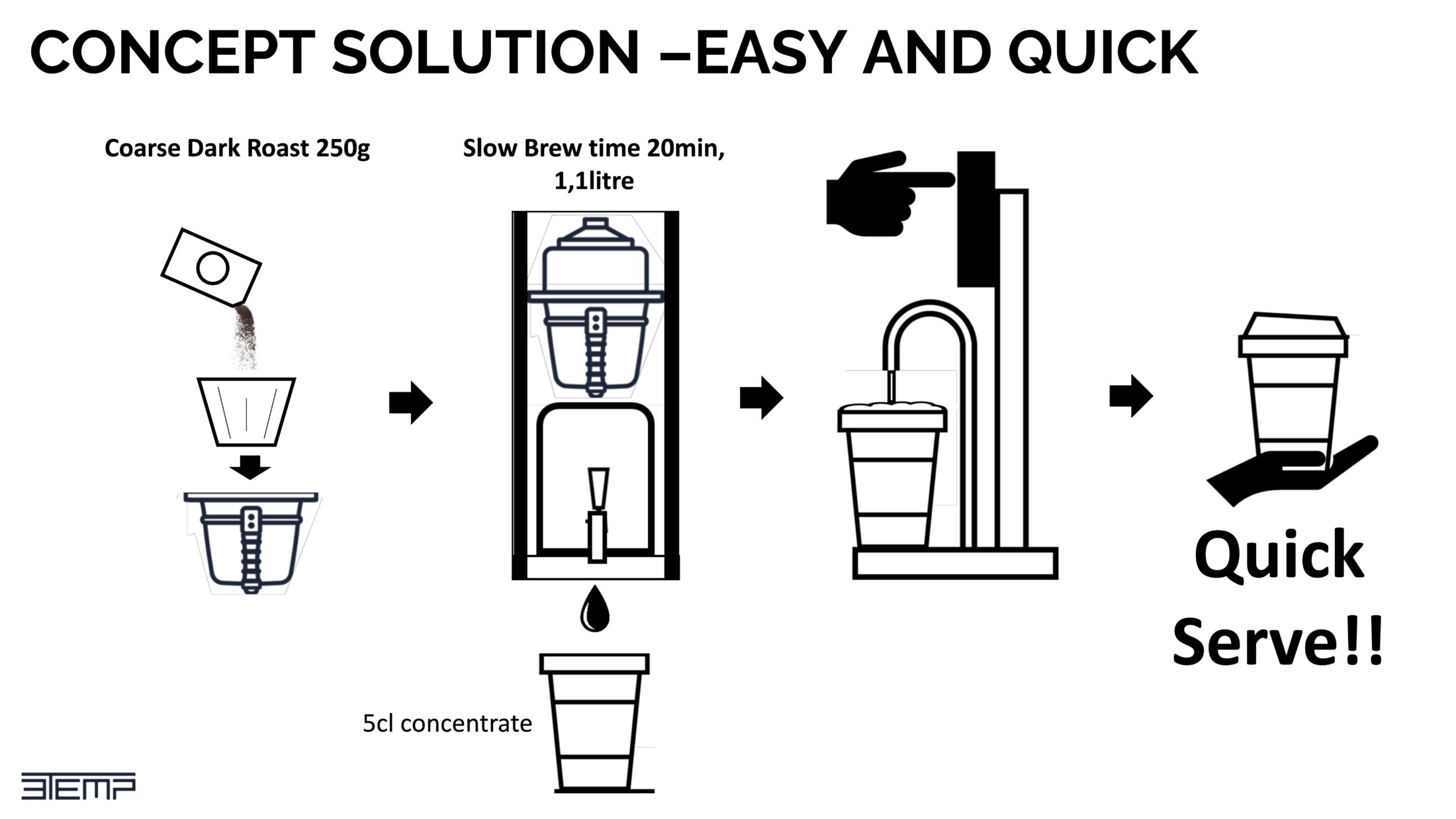

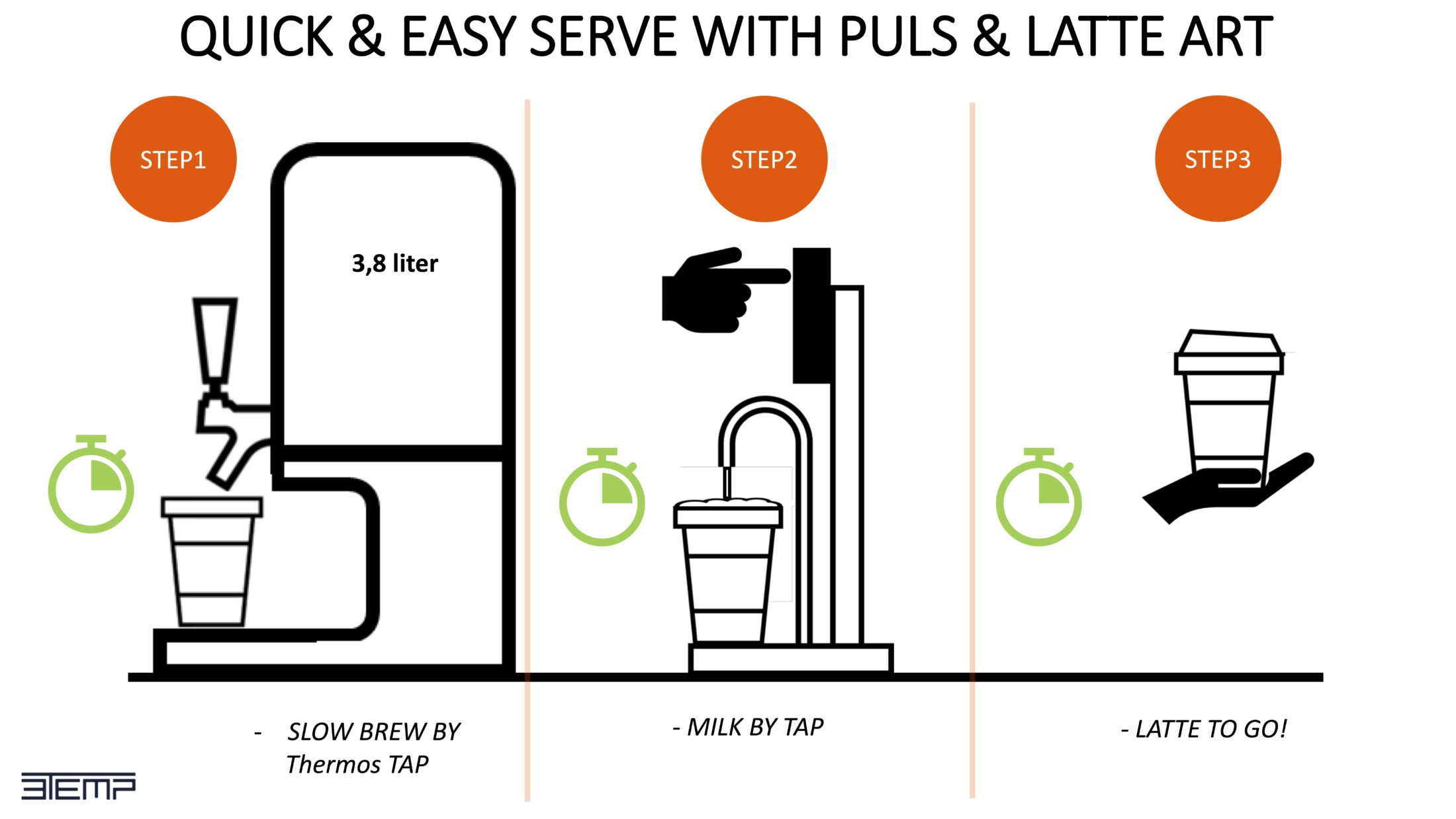

By combining Slow Brew coffee concentrate from 3TEMP with milk foaming precision from the Latte Art Factory, this new setup is redefining high-volume coffee service in venues like arenas, event centers, and stadiums.

Löfbergs is a Latte Art Factory partner in Sweden.

The Challenge: Scaling Quality in High-Volume Venues

Espresso machines and baristas remain essential to specialty coffee. But in high-traffic environments, like concert halls or sports arenas, traditional café workflows can become bottlenecks.

Speed, consistency, and ease of use become critical. Training new staff for a traditional setup is time-consuming, and equipment downtime or cleaning demands add operational strain.

That’s where this minimal solution shines.

A Smarter Workflow: Slow Brew + Latte Art Factory

This new system supports baristas in environments where speed and scale matter most.

Here’s how it works:

Result? A smooth workflow that delivers high-quality cappuccinos and lattes, at the push of a button.

No tamping. No steaming wand. No espresso station overload.

The Skagen Pilot

A second long-term test took place at a café in Skagen, Denmark, running from May to October 2023. The setup consistently delivered around 150 drinks per day, mostly lattes and cappuccinos, without requiring trained baristas. Staff received less than half an hour of training, yet maintained quality and consistency throughout the five-month period.

Reliability was another highlight: the system ran without breakdowns, needing only minor recipe adjustments along the way. With drinks priced at about €5.40 for a 33cl cup, the test confirmed that Slow Brew + Latte Art Factory isn’t just a quick fix for events, but a robust solution for everyday high-volume service.

The results confirmed what the Stockholm pilot showed: high-volume, high-quality coffee service doesn’t need traditional espresso stations or intensive workflows. Even with minimal training, staff delivered consistent results day after day, proving the setup is both reliable and scalable.

Proof in the Pour

At another major event in Stockholm, the setup delivered:

Customers praised the drink quality (especially for plant-based options) and operators noted how easy and intuitive the system was to use.

Sustainable, Scalable, and Smart

This system is fast, cost-effective, and sustainable:

30% less milk waste

100x lower idle energy use than traditional espresso machines

Shorter training time for operators

Reduced cleaning and maintenance needs

Consistent drink quality all day long

And it scales beautifully: one centralized brew station can supply multiple Latte Art Factory units across an entire venue.

Extending high-quality coffee service into new spaces where traditional setups don’t make sense, like stadiums, conference halls, and festivals, has been a challenge until now.

For these environments, Slow Brew + Latte Art Factory is proving to be a smart, sustainable, and scalable solution.

Curious how this setup could work in your business?

Let’s talk. The minimal setup future might just be your biggest upgrade yet.

Velo Cafe Huahin is a beloved café in one of Thailand’s top beach towns, which boosts speed, consistency, and sustainability with the help of the Latte Art Factory.

A destination café with a growing reputation

Located in the heart of Hua Hin, one of Thailand’s most popular weekend destinations, Velo Cafe Huahin has built a loyal following among locals and tourists alike. Known as “The Café of Hua Hin,” it’s praised for more than just its beachside charm—it’s a brand rooted in quality, speed, and sustainability. That’s exactly what led the team to discover Latte Art Factory.

Meeting the challenge of volume and consistency

On weekends and holidays, Velo Cafe Huahin can serve up to 600 cups a day—with nearly 80 drinks per hour at peak times. Around 50% of those drinks are milk-based, putting a heavy demand on speed and foam consistency.

“I’ve been looking for a solution that could prepare beverages with just the touch of a button—and I finally found it with LAF,” says owner Nattapon Sarasisang.

Since installing the LAF PRO, the café has transformed its back-of-bar operations. The machine now handles all milk-based beverages—hot and cold—helping the team keep up with demand without sacrificing quality.

Faster workflows, reliable results

Thanks to automated, high-speed milk dispensing, Velo Cafe Huahin can now serve drinks in under 3 minutes.

“It speeds up our service by 20%–30%,” the owner shares. “It really helps us handle our crazy traffic!”

By eliminating manual steaming, the team no longer struggles with inconsistent foam or temperature issues. With Latte Art Factory, every cup is precisely textured and perfectly heated, no matter who’s behind the bar.

– Nattapon, owner of Velo Cafe Huahin

Saving time, labor, and milk

With recipes stored directly in the system, even new staff can deliver drinks like seasoned baristas. That means less training time, smoother onboarding, and more time spent serving customers. Add to that the fact that it delivers consistency of quality, regardless of the barista’s skill level.

Plus, the precise milk dispensing reduces over-pouring and waste—saving on both ingredients and cost.

Built for sustainability

Sustainability is a core value at Velo Cafe Huahin. All drinks are served in recyclable aluminum cans, and Latte Art Factory supports that mission with a fast, hygienic, and low-waste approach. The machine dispenses milk directly into the cans, allowing baristas to multitask efficiently while minimizing environmental impact.

Designed to scale

With rising demand and a strong local following, Velo Cafe Huahin is growing—and Latte Art Factory is helping them scale without compromising service quality.

“The LAF helps increase the performance and speed of the team to prepare a drink. If the shop has limited staff (2-3 people), this would help to deliver drinks during rush hour quickly, so the customer wouldn’t have to wait long,” says Nattapon.

From speed and consistency to sustainability and profitability, Latte Art Factory is proving to be a perfect fit for this thriving café.

This machine was installed by our partner in Thailand, Boncafe Thailand.

Join the cafés around the world upgrading their workflow.

Discover Latte Art Factory and bring consistency to every cup.

At Société, a premium brand family of Excelso Coffee in Indonesia, quality isn’t just a goal—it’s the standard. Known for its elevated café experience, Société focuses on delivering premium beverages with exceptional consistency, no matter the day, the drink, or the barista behind the bar. With three outlets now using the Latte Art Factory, the team has found a solution that doesn’t just ensure perfect milk foam—it also simplifies their workflow and makes baristas’ lives easier, every single day.

“The taste stays consistent every day—it makes our workflow easier and keeps quality high,” says Reza, a barista at Société.

From lattes and flat whites to piccolos and cappuccinos, milk-based beverages are an essential part of Société’s menu. In a premium setting, customers expect the same flawless texture and taste in every cup—and that’s where Latte Art Factory excels.

“Because it’s already set, the taste stays consistent—we just need to execute every day,” Reza adds

Designed to deliver perfectly textured milk foam, hot or cold, dairy or plant-based—at the push of a button, Latte Art Factory ensures that baristas can focus on presentation and customer experience, knowing the quality is already taken care of.

While consistency is key in premium cafés, so is creating a great working environment for the team. For the baristas at Société, Latte Art Factory has made their daily routines simpler and more efficient.

Here’s what they value most:

“It’s easy for baristas to use. The presets make everything simple and fast—and the result is always reliable,” Reza explains.

After introducing Latte Art Factory at one location, Société quickly expanded its use to all three of its outlets, reinforcing the machine’s role in maintaining brand-wide standards. For a premium café concept like Société, that level of reliability and ease of use is key to scaling quality without compromise.

“Latte Art Factory makes my job easier while maintaining the high standards our customers expect,” says Reza.

Reach out today to discover how Latte Art Factory can help your team serve consistently exceptional drinks, simplify workflows, and elevate the entire café experience.

Adds smooth, creamy texture and visual appeal—highly “Instagrammable”.

Attracts trend-seeking consumers and allows premium pricing.

LAF makes cold foam effortless—ready at 4 °C, consistent quality, no extra training.

Classic Creamy Iced Latte – Espresso + cold milk + thick cold foam.

Iced Cappuccino – Espresso base with milk foam topping.

Cold Brew Latte – Rich cold brew finished with layers of foam.

Dreamy Iced Chocolate – Iced chocolate drink with creamy foam.

Signature Creations – Mango Coco Breeze, Toffee Banana Bliss, Salty Caramel Kiss, Golden Elixir.

Instant foam on tap; no manual frothing.

Preset textures/dosages reduce waste and speed service.

No deep barista skills needed; lowers training costs €279–899 per hire.

Market cold foam as premium add‑on.

Charge an extra €0.30 per drink = €900/month more on 1,000 drinks.

Easy to roll out seasonal or signature flavors.

Choose LAF Bar Pro for speed and capacity.

Ensure counter space, power, water, and drainage access.

Program recipes via touchscreen UI.

What’s the return on investment?

Want to expand your cold drink menu and significantly increase revenue? Reach out now and get your personalized quote.

An award-winning, steam-free automatic milk frother designed in Germany with over 30 years of coffee tech expertise.

Two main models: LAF Classic (countertop with built‑in fridge) and LAF Bar (compact dispenser with under‑counter fridge), each available in Pro versions for higher volume outlets.

High-volume coffee shops seeking quicker service and uniform quality.

Cafés aiming to incorporate dairy and plant-based milk drinks.

Businesses looking to reduce waste and operational training time.

Outlets wanting hygienic, low-effort cleaning with compliance built in.

Steamer vs Frother? Automatic milk frothers add air; steamers heat with steam—LAF covers all foam needs (including cold foam) with faster, less energy/water use

Pro versions difference? Pro units: faster (1.6 l/min) and higher throughput compared to standard’s 1.2 l/min

Power & Space? The Classic sits on counters, while Bar’s fridge is hidden; both need water, drainage, internet, 2000 W power, similar footprints

What’s the return on investment?

Ready to elevate your café? Reach out or connect with a certified partner to schedule a demo and explore ROI.

Unveil the secrets of milk frother vs. steamer technology with our

comprehensive guide tailored for café owners. From deciphering the nuances

between frothing and steaming to exploring automated frothing systems,

discover how to enhance your café’s operations and elevate the coffee

experience for your customers.

Any café owner who seeks to stay ahead in the bustling world of coffee knows the

importance of optimizing workflows and embracing innovation. In this

comprehensive guide tailored specifically for café owners, we embark on an

exploration of the intricate world of milk frothing and steaming technology.

From deciphering the subtle contrasts between frothing and steaming to

uncovering the advantages of automated frothing systems, we navigate the

possibilities to enhance your business operations.

Frothing milk is all about adding air, while steaming milk focuses on adding

steam. Depending on your equipment, frothed milk can be hot or cold, while

steamed milk is always hot.

Milk frothers infuse air into milk, creating dense foam ideal

for cappuccinos and cold foam drinks. This foam maintains its texture and offers

a creamy consistency with less water content.

Milk steamers heat and texture milk using steam infusion,

producing “microfoam” with small, velvety bubbles. Steamed milk is often used in

lattes, flat whites, hot chocolates, and more. By incorporating both methods

into your menu, you cater to a wider range of tastes, enhancing customer

satisfaction and distinguishing your café.

Both milk frothers and steamers come in manual and automatic versions. Manual

models require hands-on operation, while automatic models streamline the

process, ensuring consistency in high-volume cafés.

Choosing equipment that covers all essential features is key. The

Latte Art Factory

stands out by offering everything needed for high-quality milk foam production

in cafés. With LAF, you get:

The Latte Art Factory (LAF) offers telemetry-based data

insights, helping optimize workflows and enhance customer satisfaction.

LAF dispenses precise milk amounts, reducing wastage. With extra fridge space

under the counter, batch frothing becomes unnecessary.

LAF requires minimal training, making it ideal for cafés with high staff

turnover. Consistent results reduce wastage and training costs.

LAF’s cold foam capabilities allow cafés to create innovative menu options that

attract customers seeking cold coffee drinks.

As technology advances, innovations such as AI-driven foam optimization and

improved cold foam capabilities are expected to shape the future of cafés. By

assessing your café’s needs and keeping an eye on future trends, you can ensure

long-term success and deliver exceptional coffee experiences to your customers.

Unveil the secrets of milk frother vs. steamer technology with our comprehensive guide tailored for café owners. From deciphering the nuances between frothing and steaming to exploring automated frothing systems, discover how to enhance your café’s operations and elevate the coffee experience for your customers.

Any café owner who seeks to stay ahead in the bustling world of coffee knows the importance of optimizing workflows and embracing innovation. In this comprehensive guide tailored specifically for café owners, we embark on an exploration of the intricate world of milk frothing and steaming technology. From deciphering the subtle contrasts between frothing and steaming to uncovering the advantages of automated frothing systems, we navigate the possibilities to enhance your business operations.

Frothing milk is all about adding air, while steaming milk focuses on adding steam. Depending on your equipment, frothed milk can be hot or cold, while steamed milk is always hot.

Milk frothers infuse air into milk, creating dense foam ideal for cappuccinos and cold foam drinks. This foam maintains its texture and offers a creamy consistency with less water content.

Milk steamers heat and texture milk using steam infusion, producing “microfoam” with small, velvety bubbles. Steamed milk is often used in lattes, flat whites, hot chocolates, and more.

By incorporating both methods into your menu, you cater to a wider range of tastes, enhancing customer satisfaction and distinguishing your café.

Both milk frothers and steamers come in manual and automatic versions. Manual models require hands-on operation, while automatic models streamline the process, ensuring consistency in high-volume cafés.

Choosing equipment that covers all essential features is key. The Latte Art Factory stands out by offering everything needed for high-quality milk foam production in cafés.

With LAF, you get:

The Latte Art Factory (LAF) offers telemetry-based data insights, helping optimize workflows and enhance customer satisfaction.

LAF dispenses precise milk amounts, reducing wastage. With extra fridge space under the counter, batch frothing becomes unnecessary.

LAF requires minimal training, making it ideal for cafés with high staff turnover. Consistent results reduce wastage and training costs.

LAF’s cold foam capabilities allow cafés to create innovative menu options that attract customers seeking cold coffee drinks.

As technology advances, innovations such as AI-driven foam optimization and improved cold foam capabilities are expected to shape the future of cafés.

By assessing your café’s needs and keeping an eye on future trends, you can ensure long-term success and deliver exceptional coffee experiences to your customers.

5 to go and Latte Art Factory have been partnering for almost two years, and in that time both companies have been growing hand in hand. Today, 5 to go is one of the fastest growing coffee chains in Europe with 500 outlets across the continent. More than 100 5 to go outlets now have a Latte Art Factory.

In the increasingly competitive coffee industry, cafés are facing a dual challenge: barista wages are rising year over year, while the bottom line is under pressure from escalating operational costs and the price of goods.

Amid these challenges, the Latte Art Factory (LAF) emerges as a groundbreaking solution, offering a way to not only sustain but also enhance profitability.

Lucian Bădilă and Radu Savopol, founders of 5 to go

At 5 to go, a detailed analysis shows that 85% of the coffees sold by the chain are milk-based, with “Mr. Big”, a 475ml cappuccino, reigning as the customer favorite.

This preference underscores the importance of milk in their business model, but also highlights the vulnerability to increasing costs of milk waste as a result of traditional barista-prepared beverages.

“I recommend it wholeheartedly! I admit that I was a little sceptical at first, but it’s worth the money. It is a real help during peak hours, we don’t risk milk foam quality with new employees, and the consumption of milk has decreased for us.”

Iulia, owner of a 5 to go coffee shop

As operational expenses climb, threatening the financial health of cafés, Latte Art Factory stands out as the hero. By integrating this innovative machine, café owners can navigate the shifting challenges and changing trends of the coffee industry with greater ease and efficiency. Today’s coffee consumers value quality above all and variety of beverages, including drinks with cold foam.

“After just a week of using the Latte Art Factory, I can say that it is worth every penny. The milk foam is perfect, milk losses are reduced to almost zero and the cold milk foam is incredible. In terms of waiting times for a coffee with milk, they have halved. Worth the investment!”

Cebedal, owner of another outlet

For Mihai Dadiloveanu, owner of the 5 to go Eroilor branch in Bucharest, the introduction of the automatic milk frothing machine was nothing short of transformative.

Witnessing a 54% surge in revenue within a year of using the Latte Art Factory, compared to the previous year without it, Mihai’s experience serves as a compelling testament to the machine’s value.

He notes the significant business growth attributable to Latte Art Factory and praises its cost-effectiveness and efficiency, which have enabled him to serve a larger customer base without the necessity for top-tier baristas.

“Latte Art Factory is synonymous with quality, and that’s what people look for,” he adds.

The numbers speak for themselves: The LAF not only paid for itself within months but also helped double the production of milk-based coffees from 150 to 300 per hour.

Additionally, the machine’s efficiency and precise dispensing has led to a significant reduction in milk waste, saving Mihai 11.7 liters of milk daily, amounting to 3,000 euros saved each year.

5 to go was born from the desire of the founders Radu Savopol and Lucian Bădilă to offer quality coffee-based drinks, at a fair price.

The chain was nominated for Best Coffee Chain in Central/Eastern Europe at the 2023 European Coffee Awards gala in Barcelona, and Radu Savopol, co-founder of 5 to go, won the Outstanding Contribution to the European Coffee Industry award.

The Latte Art Factory also boasts three SCA Best New Product awards from 2022 and 2023, as well as the 2023 Smart Label HOST Innovation Award.

“The advanced milk frothing technology provided by Latte Art Factory is beyond a doubt a significant asset for a café. On the one hand, the milk cream obtained in this way is a consumer satisfaction factor, on the other hand, it is an element that brings profitability to the business, contributing to a superior taste experience delivered without the need for long-term employee training – after 2 days of training, even beginners are ready to achieve the ideal product texture with this machine. This saves time – 30% more milk-based coffee products can be produced in one day, improves staff efficiency – more coffee is delivered in less time, and milk wastage is significantly reduced because the machine uses only the amount needed, without compromising the result.”

Radu Savopol, co-founder of 5 to go

“The positive feedback received from 5 to go franchisees is most relevant for us, as saving resources and significantly reducing waiting time are two essential elements for streamlining a business in the coffee industry, in a context where cost reduction is now a main objective. Specifically, the use of Latte Art Factory has resulted in a 30% increase in revenue in the 5 to go coffee shops where we have these machines, a promising result that we are pleased with and demonstrates the potential of the technology that we have brought to Romania as sole importer and distributor in 2022. We are proud of this partnership and have every reason to take it further.”

Lucian Bădilă, co-founder of 5 to go

The story of 5 to go demonstrates the impact the Latte Art Factory can have on the coffee industry. By offering a solution that enhances efficiency, reduces costs, and maintains the highest quality of milk-based beverages, the LAF is redefining the operational model for cafés.

Its success at 5 to go signals a promising outlook for others in the industry seeking to navigate the challenges of rising costs and consumer demand for quality.